Previous

Next

Silicon Masterbatch

Silicon Masterbatch

Silicon masterbatches are specialized additives used in various plastic and rubber applications

Composition

- Silicon masterbatches consist of ultra-high molecular weight siloxane polymers dispersed within different thermoplastic resins (such as PE, PP, PA, etc.).

- These white pellets enhance the flow of the resin during processing and modify surface properties.

- Silicon masterbatch consists of vinyl silicon polymers that are compounded with silica. These masterbatches are designed to enhance specific properties in various formulations.

Purpose

- Flow Enhancement: They improve mold filling, mold release, and reduce extruder torque, resulting in faster throughput.

- Surface Modification: Silicone masterbatches enhance surface quality, reduce the coefficient of friction, and provide greater abrasion and scratch resistance.

Common Applications of Plast Clarify

Rubber

Silicon Hoses

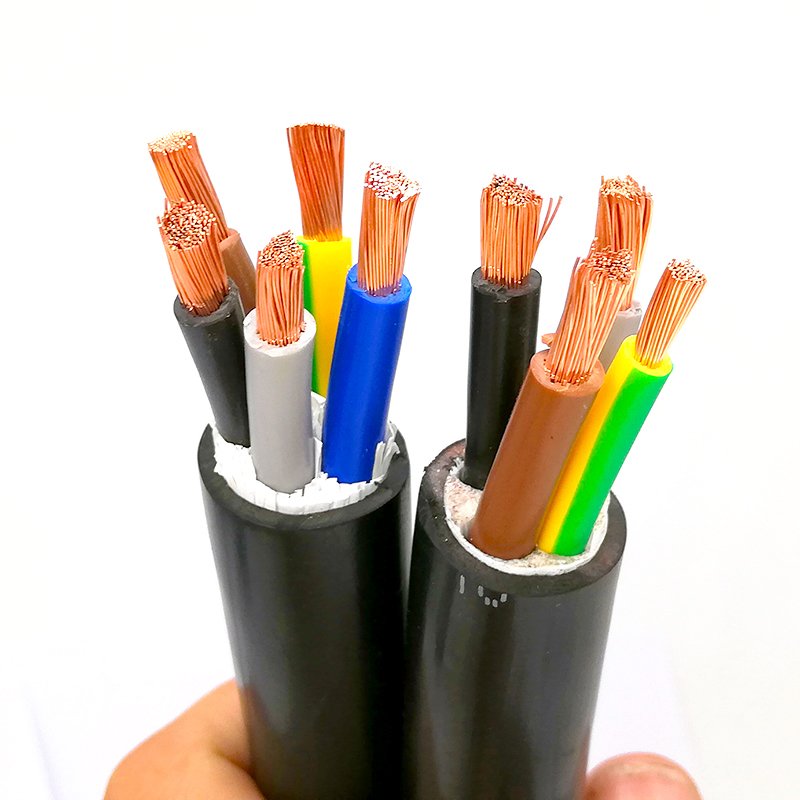

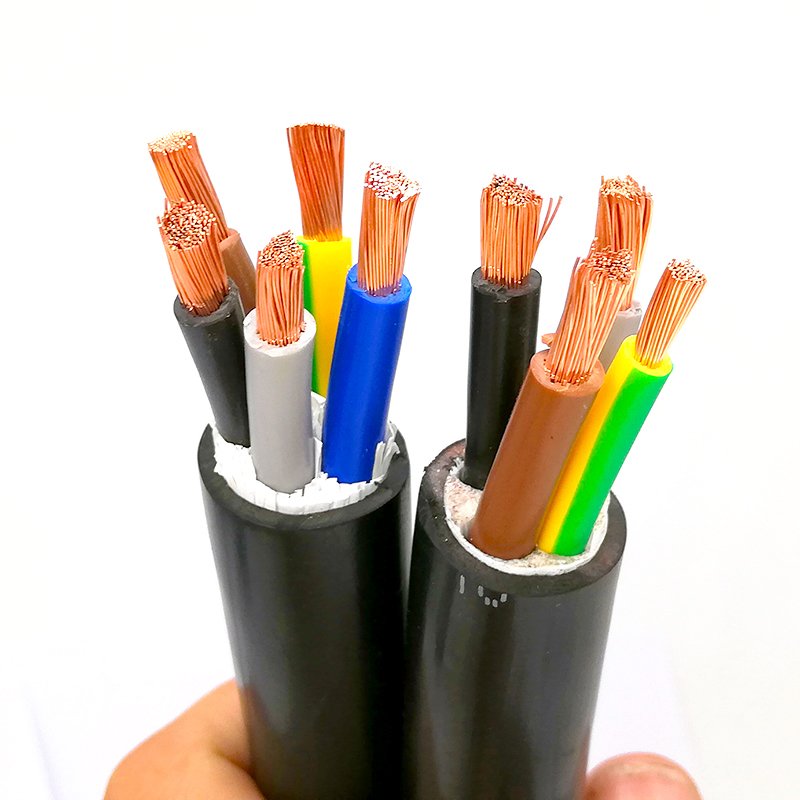

Cable insulation

Weatherstripping

Waterproofing Materials

Silicon Sealant

Bakeware

Gaskets

Properties Of Silicon Masterbatch

Ease of Use

By scattering light, these masterbatches eliminate concentrated areas of intense brightness.

Property Enhancement

They effectively disperse light, making it more uniform and gentle

Abrasion Resistance

Silicone masterbatches help improve the abrasion resistance of the final products.

Reduced Friction

By minimizing the coefficient of friction, they enhance the material’s performance.

Lubricity

They impart lubricity, making the material smoother and easier to work with.

Previous

Next