RECYCLING

APPLICATION

Reprocessing is a process of using those waste plastics or by-products which were generated during manufacturing of plastic materials whilst Recycling is the process of treating the once consumed plastic materials in such a way that it could be again used in production of further Plastic materials.

Reprocessing is a multistep process that includes cleaning, inspection and assembly, functional testing (if applicable), packaging and labelling and storage.

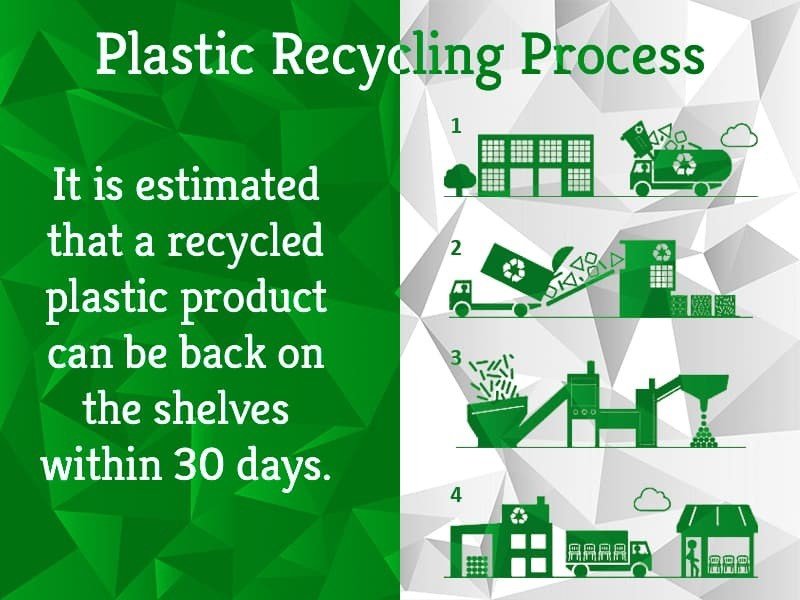

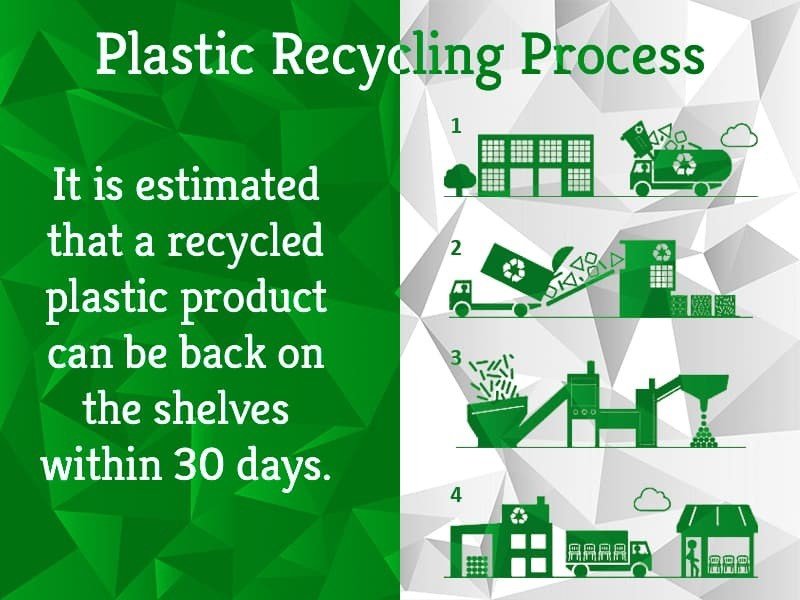

Recycling is a process that involves collection, sorting, washing, resizing, identification and compounding. The first step of polymer recycling is the collection of waste polymer, which is to be processed for recycling.

Advantages of Reprocessing & Recylcing are given below :

It Conserves Energy

Reduces Air and Water Pollution

Reduces

Greenhouse Gases

Conserves

Natural Resources

Facilitates

Circular Economy

3 Stages of Plastic waste prior to Recycling

- While Manufacturing ( Post production)

- When Packing is done

- During Collection

-

i. B 2 B ( Customer to Customer)

ii. B 2 C ( Customer to Consumer )

In General , we can classify waste in to 3 grades namely

- Post production wastage as “A” Grade

- B 2 B (ie) Customer to Customer wastage as “ B” Grade

- B 2 C (ie) Customer Consumer wastage as “C” Grade which may comprise of Grades “A” & “B” as well.

In all the above cases of Plastic waste collected and seggregated , we need to do Washing by air & water before pursuing into subsequent steps of Recycling.Plastic has become such an integral part of our lives, but it has also clearly become an environmental problem. Reduce, reuse and recycle are the keys to reducing waste.

-

REDUCE:

It emphasizes on reduction of non-essential usage of plastics to the best possible extent we can. For instance, soft plastics are often impossible to recycle because they get caught in moving machine parts, causing them to get stuck sometimes. We can expedite the feasibility to switch over to a harder plastic like PET which can be recycled. -

REUSE:

Although reusing plastics at the manufacturing stage can be hard but it’s viable, for instance, by using 3D Printing & another way is to make sure that the product has individual pieces that are easy to maintain or change. This will enable to repair and re-use the plastic products instead of buying a replacement. -

RECYCLE:

In spite of complexity in this process, nevertheless we can make the “Best” from “Waste”, it all begins with sorting the plastic by type. There are seven types of difference types of plastics as shown below :

Steps involved in Plastic Recycling

Significance of Recycling - Need of the hour

Read More

Having identified selective sectors , key driver being Packaging segment, WE at BAJAJ is mobilizing our best resources by providing masterbatches to ensure that highest degree of Plastics in Packaging segment is being recycled . In order to facilitate such a formidable task, major challenges are emerging in terms of sorting of waste to produce a high- quality Post consumer recyclate (PCR) & issues related to stabilization, coloration, safety & processing.

WE at BAJAJ offer below products to cater this segment

Anti Oxidant additive masterbatch

Dessicant Masterbatch

Processing Aid Masterbatch

During the processing of recycled PE resin into a recycled film, the output is often limited by the converter’s production capacity & need for additional equipment for optimizing productivity. Also, recycled PE can be prone to degrade during processing which can also impact processing efficiency to a greater extent, as a solution, our PPA could increase recycled film output and drive the demand for recycled PE resin without the need for significant additional equipment investment. It facilitates sustainable film solutions ( Post consumer PE film) leading to profitability for the converters .

Odour Remover

Therefore, there’s a need to efficiently & environment friendly decontaminate these domestic plastic waste for subsequent use as a raw material in order to reduce their presence in landfills, to reduce operating costs in the recycling industry, as well as to increase the added value of the product.

We do offer our PLAST ODOUR NEUTRALIZER which acts by oxidation of Odour creating substances or by absorption. They do react on a molecular level to neutralize odours in PCR without relying on chemicals. The fundamental mechanisms involved are adsorption, absorption, gas solubility and reaction.